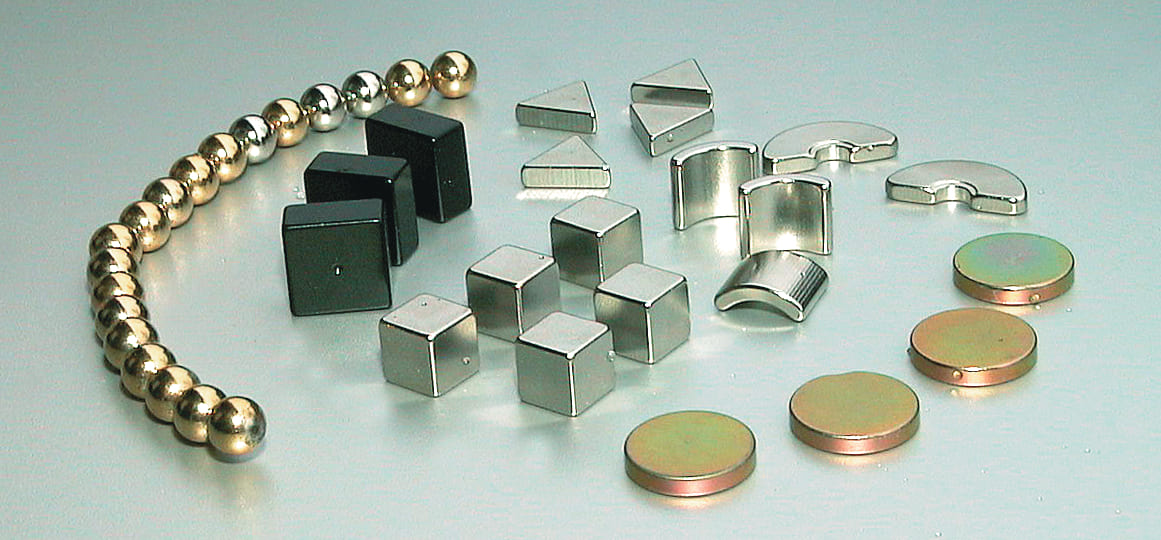

Customized Neodymium Permanent Magnets

Permanent magnets are used for a wide variety of applications in all fields. Depending on the requirements, the optimum raw magnet and the right surface coating must be selected. Motors, generators, sensors - almost everything that moves is based on magnetism!

Make an inquiry

The following magnet materials are used in industry:

Neodymium magnets must be surface treated to protect against corrosion. Usually the magnets are coated. Especially for motor magnets, however, the process of passivation by heat treatment is also recommended. The most common coatings are nickel, zinc and epoxy resin. The coatings have the following properties.

NdFeB magnet materials are produced by a press-sintering process and mechanically machined after the sintering process to produce the desired shape. Rare earth magnets are very brittle and not easy to machine. The higher the maximum working temperature of the material, the more brittle the material. In the following table you will find the physical properties of NdFeB standard material:

Iron poles can cause a higher force line density in the magnetic circuit. This leads to a significantly improved adhesion effect, since the magnetic flux can be redirected and concentrated on the adhesive surface. An approximate increase factor for the lifting power is given in the sketches shown.

An important quality characteristic for NdFeB magnets is their dimensional accuracy, as some tolerances are very difficult to maintain, depending on the shape. If possible, refrain from unnecessarily tight tolerances in the design. This will make it easier for you to install the magnets.